Your How to dry fresh cut pine lumber images are available in this site. How to dry fresh cut pine lumber are a topic that is being searched for and liked by netizens today. You can Find and Download the How to dry fresh cut pine lumber files here. Download all royalty-free photos and vectors.

If you’re looking for how to dry fresh cut pine lumber pictures information linked to the how to dry fresh cut pine lumber topic, you have visit the right site. Our website frequently provides you with suggestions for seeking the highest quality video and image content, please kindly hunt and find more enlightening video articles and images that match your interests.

How To Dry Fresh Cut Pine Lumber. Join the WWGOA community to access a huge library of woodworking instructional videos. To effectively cure a slab for use in a table or other specialty item its critical that you adhere to specific steps. Select only straight-grained defect-free boards no thicker than 2 and less than 12 wide. Fill the container with Pentarcryl if the wood is freshly cut.

Spalted Norfolk Island Pine Available In Turning Stock And Slabs At Funktionhouse Com Wood Slab Wood Species Wood From pinterest.com

Spalted Norfolk Island Pine Available In Turning Stock And Slabs At Funktionhouse Com Wood Slab Wood Species Wood From pinterest.com

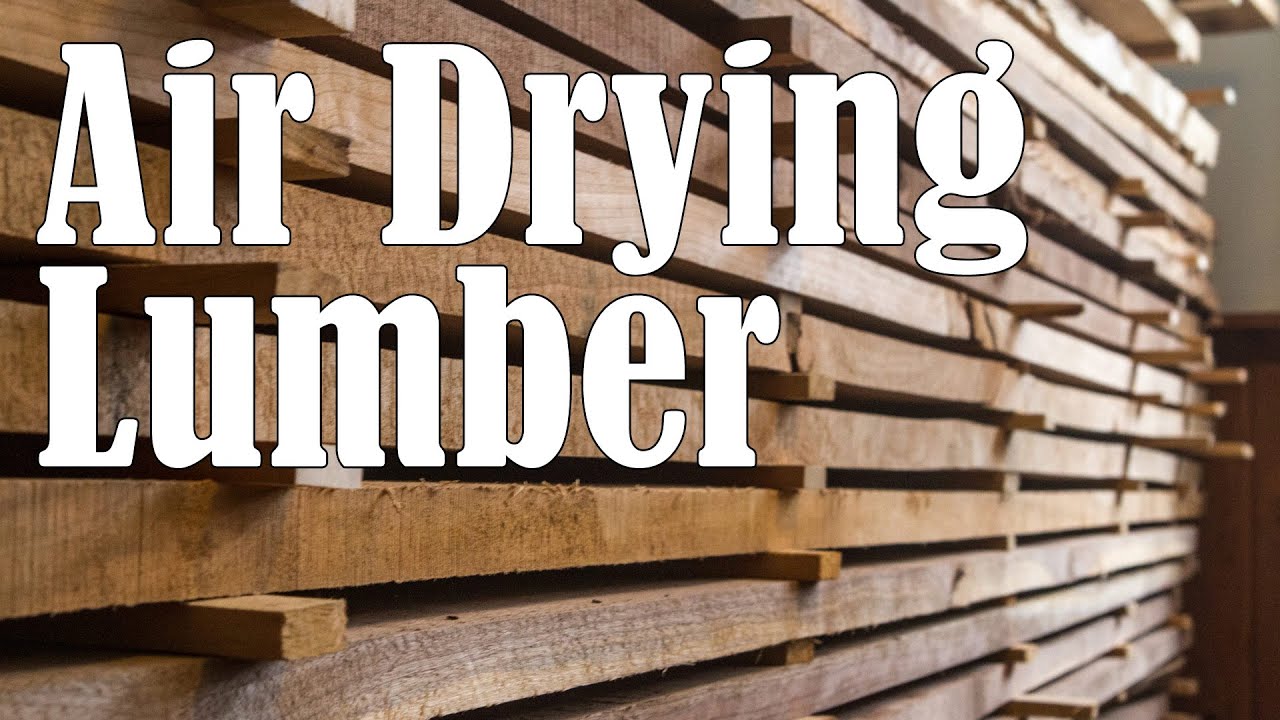

Use the formula of 1-inch of thickness per year for the curing time. If youre using plywood laying out the plywood and letting it air-dry will ensure the best quality of wood. Drying wood in the shop. With really nice boards we lean them against the shed and flip them every few hours so that the sun dries them down quite a bit. The object is to circulate air around and through it. Take the boards you want to dry and start stacking them on the stickers starting with the first layer of course.

For pine we want to keep free of mold we load the kiln about half full and crank up the heat and fans.

Fill the container with Pentarcryl if the wood is freshly cut. This method will increase the airflow to each piece of wood. If the design allows for shrinkage without damaging the wood or causing joints to loosen you can use air-dried lumber. If youre drying green pine that youve milled select a location outdoors on high ground with prevailing winds. You cut the trees around you and you built your house. Ideally fresh cut lumber should have a moisture content of between 15 and 20 percent.

Source: pinterest.com

Source: pinterest.com

Pentacryl is a specially formulated wood stabilizer thats designed to keep green or fresh wood from cracking as it dries. The bundles are set out in the sun where they can get the most wind. No one kild dried their lumber. For pine we want to keep free of mold we load the kiln about half full and crank up the heat and fans. So in this video I will go over.

Source: woodshopnews.com

Source: woodshopnews.com

Check the stack occasionally. With really nice boards we lean them against the shed and flip them every few hours so that the sun dries them down quite a bit. The most common method used to air-dry lumber is to lay narrow sticks perpendicular to the layers of lumber to create an air space between each layer so the moisture can escape. My understanding is that all homes over 100 years old were built out of green lumber. Actually a hole gets smaller when the wood dries and shrinks.

Source: wood-database.com

Source: wood-database.com

The bundles are set out in the sun where they can get the most wind. If youre using plywood laying out the plywood and letting it air-dry will ensure the best quality of wood. From Professor Gene Wengert forum technical advisor. Take the boards you want to dry and start stacking them on the stickers starting with the first layer of course. A good foundation is critical to successfully drying wood.

Source: pinterest.com

Source: pinterest.com

Air needs to be able to travel between boards for drying. Use the formula of 1-inch of thickness per year for the curing time. If the base is not even the lumber will dry with the contour of the base so it must be as flat and straight as you can get it. My understanding is that all homes over 100 years old were built out of green lumber. However the actual moisture content depends on the weather.

Source: woodshopnews.com

Source: woodshopnews.com

Then youll need to check the moisture level every few days. How long should pine dry before building. Try drilling a hole in green wood and measure it then check it later when it has had time to dry. Get it cut seal the cut ends slab it with a chainsaw or split it into whatever size is manageable raise it off the ground and get it stacked and stickered in a windy shaded spot with some kind of cover over the top. Make sure that the wood you are drying is laying perpendicular on the stickers and make sure to leave about an inch of space in between each piece of wood.

Source: popularwoodworking.com

Source: popularwoodworking.com

If the design allows for shrinkage without damaging the wood or causing joints to loosen you can use air-dried lumber. Across the main supports lay more supports at 2 foot spacing and this is what your lumber is going to be. The stickers between rows can cause staining that can run quite deep and ruin your wood for some high end projects so make sure they are kiln dry and use your router to cut grooves every half inch at 45 degree angles on both sides of the sticker. The object is to circulate air around and through it. After boards are cut in the sawmill they need to be stack properly.

Source: pinterest.com

Source: pinterest.com

No one kild dried their lumber. Select only straight-grained defect-free boards no thicker than 2 and less than 12 wide. To effectively cure a slab for use in a table or other specialty item its critical that you adhere to specific steps. However the actual moisture content depends on the weather. So in this video I will go over.

Source: pinterest.com

Source: pinterest.com

Click to see full answer. Use the formula of 1-inch of thickness per year for the curing time. How long should pine dry before building. Excessive checking means drying too fast. You can do this at any point in the drying process.

Source: youtube.com

Source: youtube.com

If youre drying green pine that youve milled select a location outdoors on high ground with prevailing winds. Step 2 - Long Cuts with the Grain. If youre drying green pine that youve milled select a location outdoors on high ground with prevailing winds. Stains or mildew signal drying too slowly. From Professor Gene Wengert forum technical advisor.

Source: pinterest.com

Source: pinterest.com

However the actual moisture content depends on the weather. Do it as soon as possible because the tree was already dyingdead and rot and decay will set in within days to a couple weeks with direct contact with the ground even though. Use the formula of 1-inch of thickness per year for the curing time. Most kiln dried lumbar is not properly dried. Httpsbitly38h8RoKWood Tips - George Vondriska provides tips on h.

Source: pinterest.com

Source: pinterest.com

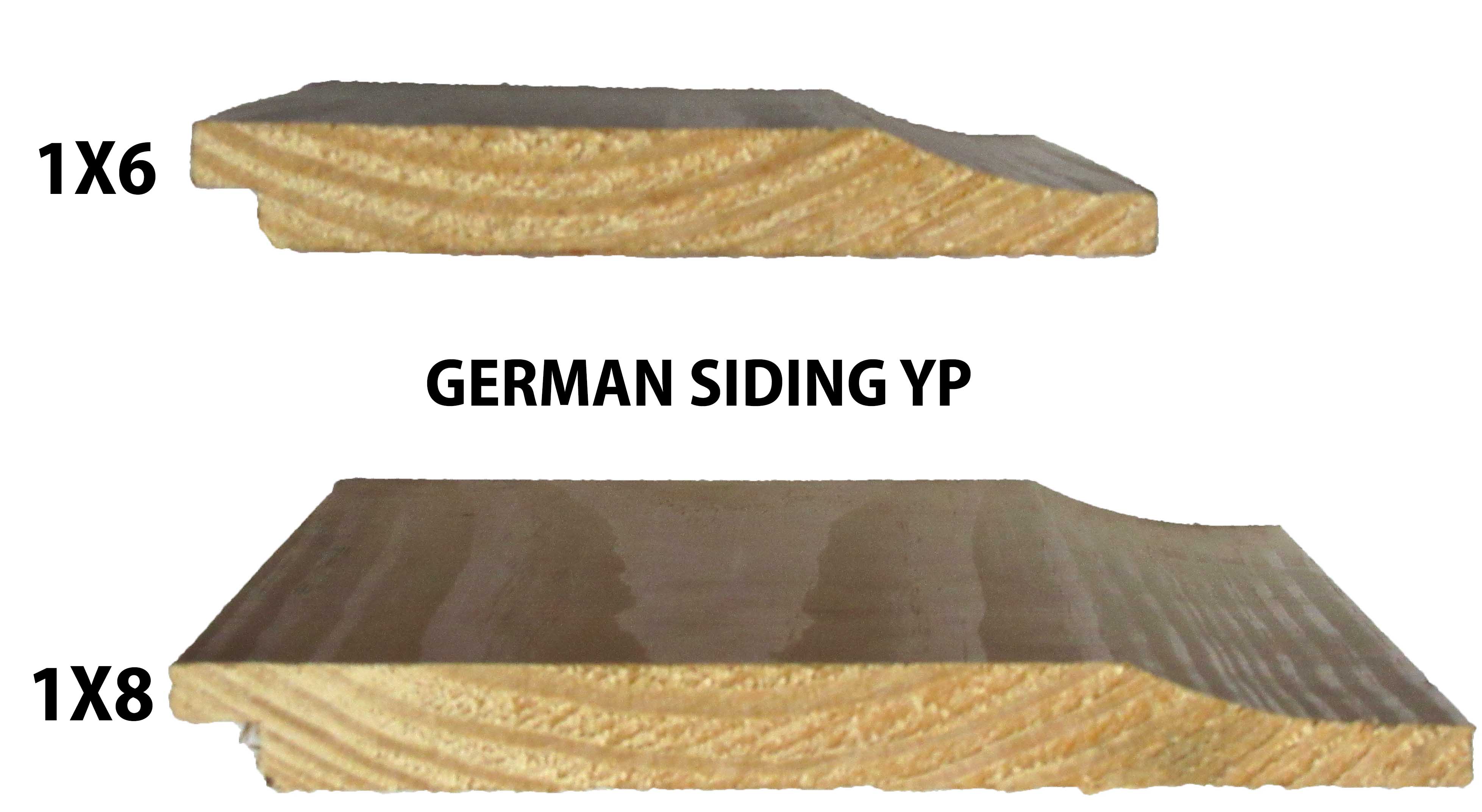

Place the slab out of direct sunlight rain and weather. Place a row of stickers on the floor or earth parallel to each other. When making strip siding using pine lumber you want to ensure the wood has been dried and treated before cutting it to avoid burn and warping of the woodAs an example with a table saw you can mark off one end of your pine plank at 45 degrees and adjust your saw to cut down through the plank length. In a moist climate green pine can take up to a year to dry to 19 percent. A good foundation is critical to successfully drying wood.

Source: youtube.com

Source: youtube.com

The stickers between rows can cause staining that can run quite deep and ruin your wood for some high end projects so make sure they are kiln dry and use your router to cut grooves every half inch at 45 degree angles on both sides of the sticker. You cut the trees around you and you built your house. What is happening is that the wood around the hole is shrinking and that makes the hole get smaller. My recommended procedure is to dry to 12-14 moisture make sure the boards are straight on the edges butt them up against each other without gaps and cover with 2 battens alternately nailed up and down the batten nails not placed across from each other. If your wood slice was recently cut and hasnt had a chance to air-dry yet fill your container with Pentacryl to soak your wood.

Source: pinterest.com

Source: pinterest.com

This will minimize surface contact while still providing the support you need to keep your wood flat and provides. These 1-inch thick pieces of lumber are unsung heroes responsible for preserving maximizing the value of your milled lumber. Most kiln dried lumbar is not properly dried. So in this video I will go over. Actually a hole gets smaller when the wood dries and shrinks.

Source: pinterest.com

Source: pinterest.com

Use the formula of 1-inch of thickness per year for the curing time. You can do this at any point in the drying process. Across the main supports lay more supports at 2 foot spacing and this is what your lumber is going to be. How long should pine dry before building. In a moist climate green pine can take up to a year to dry to 19 percent.

Source: alibaba.com

Source: alibaba.com

Drying wood in the shop. Excessive checking means drying too fast. This method will increase the airflow to each piece of wood. These main supports should be separated about 3 feet apart. Actually a hole gets smaller when the wood dries and shrinks.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to dry fresh cut pine lumber by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.